Artificial intelligence (AI) is revolutionizing the field of 3D printing by enhancing design capabilities and improving production efficiency. The convergence of AI and 3D printing technology allows for faster and more precise design iterations, automation of manufacturing processes, improved quality control, and the development of innovative materials. AI has the potential to transform various industries, including automotive, aerospace, healthcare, and construction.

Key Takeaways:

- AI in 3D printing enables faster and more precise design iterations.

- Automation of manufacturing processes through AI improves efficiency.

- AI-driven design allows for the development of innovative materials.

- AI has the potential to transform industries such as automotive, aerospace, healthcare, and construction.

- Integrating AI with 3D printing contributes to design innovation and production efficiency.

Generative Design: Optimizing 3D Printing with AI

The integration of generative design with AI has revolutionized the field of 3D printing, opening up new possibilities for optimizing designs and improving manufacturing processes. Generative design, powered by AI algorithms, enables designers to create complex and optimized structures that were previously unattainable with traditional design methods. By analyzing a set of parameters and constraints, AI algorithms generate lightweight and strong structures that maximize performance while minimizing weight.

The aerospace and automotive industries, in particular, have benefited greatly from the application of generative design in 3D printing. Lightweight structures are crucial in these industries to improve fuel efficiency, enhance performance, and reduce material costs. With generative design, designers can explore a vast range of design options and quickly iterate through different variations to find the most optimized solution. This speeds up the innovation process and allows for the production of customized components with unique geometries tailored to specific applications.

The integration of generative design with AI has revolutionized the field of 3D printing, opening up new possibilities for optimizing designs and improving manufacturing processes.

Generative design, when combined with the capabilities of 3D printing, offers numerous advantages in terms of design innovation and production efficiency. The ability to create lightweight structures not only reduces material waste but also contributes to sustainability efforts by minimizing the overall environmental impact of manufacturing processes. Furthermore, by leveraging AI-driven generative design, companies can achieve cost savings through material optimization, streamlined manufacturing processes, and faster time-to-market for new products.

| Advantages of Generative Design in 3D Printing | Examples |

|---|---|

| Optimized performance: AI algorithms generate designs that maximize strength while minimizing weight, leading to improved performance in industries like aerospace and automotive. | Aerospace components: Generative design produces lightweight and strong components for aircraft, reducing fuel consumption and increasing efficiency. |

| Innovation and customization: Generative design enables the creation of complex geometries and customized structures that can meet specific application requirements. | Customized automotive parts: Generative design allows for the production of unique automotive components tailored to specific vehicles, improving performance and aesthetics. |

| Efficient material usage: By optimizing designs, generative design reduces material waste and contributes to sustainability efforts. | Sustainable manufacturing: Generative design minimizes material waste and contributes to sustainable manufacturing practices, reducing the overall environmental impact. |

Generative design, driven by AI, has the potential to revolutionize various industries by pushing the boundaries of design innovation, enhancing performance, and accelerating manufacturing processes. As AI technology continues to advance, we can expect even more sophisticated generative design algorithms that will unlock new possibilities and further optimize 3D printing capabilities.

Automation and Accuracy: AI-driven Manufacturing in 3D Printing

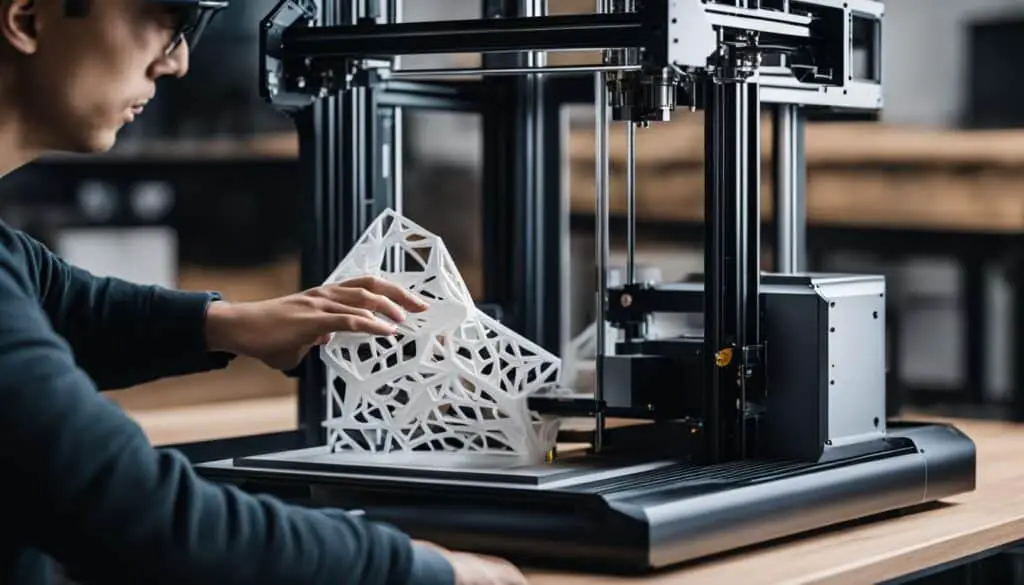

AI is transforming the field of 3D printing by revolutionizing the manufacturing process, improving efficiency, and ensuring accuracy. With AI-driven automation, various aspects of the printing process can be controlled, leading to precise and efficient production. This level of automation enables manufacturers to optimize their supply chain, reducing costs and improving overall efficiency.

One of the key advantages of AI in 3D printing is its ability to detect and correct printing errors in real-time. By continuously monitoring the printing process, AI algorithms can identify any issues or deviations from the design specifications and make immediate adjustments. This not only improves the accuracy of 3D-printed parts but also minimizes waste and reduces the need for manual intervention.

The Importance of Accuracy in Medical Implants

In the field of healthcare, where precision is paramount, AI-driven manufacturing in 3D printing has significant implications. Medical implants, such as prosthetics or dental implants, require precise customization to fit the patient’s unique anatomy. AI algorithms can analyze medical imaging data and generate optimized designs for these implants, ensuring a perfect fit and improved patient outcomes.

Additionally, AI can contribute to the development of new materials for 3D printing, further enhancing the accuracy and functionality of medical implants. By combining AI with advanced material science, manufacturers can create implants that are not only biocompatible but also possess the necessary mechanical properties for long-term durability.

Overall, AI-driven manufacturing in 3D printing brings automation, accuracy, and efficiency to the forefront of the industry. The ability to control the printing process, optimize the supply chain, and detect errors in real-time allows manufacturers to produce high-quality, customized, and precise parts. As the technology continues to advance, the applications of AI in 3D printing will further expand, revolutionizing various industries and driving innovation.

AI and Sustainability: Advancing Green Manufacturing in 3D Printing

When it comes to sustainable manufacturing, the combination of AI and 3D printing is paving the way for a greener future. By leveraging AI’s capabilities, we can optimize 3D object designs to minimize material waste and promote more efficient resource utilization. This reduction in material waste not only contributes to sustainable practices but also leads to overall cost reductions in production.

Furthermore, AI algorithms can develop new printing processes that are energy-efficient, reducing the environmental impact of 3D printing. Through intelligent optimization and automation, AI-driven printing can significantly decrease energy consumption, making the manufacturing process more sustainable and eco-friendly.

By embracing AI in 3D printing design, we can achieve the goals of sustainable manufacturing and contribute to the circular economy. The integration of AI technologies not only improves efficiency but also reduces our carbon footprint. As industries shift towards more sustainable practices, the impact on the environment will be minimized, ensuring a better future for generations to come.

FAQ

How is AI revolutionizing the field of 3D printing?

AI enhances design capabilities, improves production efficiency, speeds up innovation, and enables the development of innovative materials.

What is generative design and how does it work with 3D printing?

Generative design, powered by AI, allows designers to create complex and optimized designs. AI algorithms analyze parameters to generate lightweight and strong structures, maximizing strength while minimizing weight.

How does AI automate the 3D printing process?

AI algorithms control the printing process, ensuring accurate and efficient production. They also optimize the supply chain and enable real-time detection and correction of printing errors.

How does AI contribute to sustainability in 3D printing?

AI optimizes 3D object designs to minimize material waste, develops energy-efficient printing processes, and helps achieve sustainable manufacturing practices.

Source Links

- https://www.fictiv.com/articles/5-ways-ai-is-impacting-3d-printing

- https://medium.com/@Nontechpreneur/generative-ai-is-revolutionizing-3d-printing-8605c3c080ff

- https://www.azom.com/article.aspx?ArticleID=22451